Need :

When your business depends on electrical machinery and equipment for increased productivity and improved cash flow, it is extremely important to keep that machinery inspected and well-maintained on a regular basis. Preventive electrical equipment maintenance done regularly by trained, professional and experienced electrical workers helps to detect electrical problems before they become serious issues. By scheduling routine maintenance checks that utilize advanced technology and expert electrical skills, the industrial equipment and machinery on which your business runs can continue working efficiently, reducing the risk of a catastrophic failure that can cost time and money. Read on to learn the benefits of preventive electrical equipment maintenance, as well as the use of infrared thermography in detecting electrical problems.

Save Time and Money:

An effective preventive electrical maintenance program involves scheduling routine inspections and checkups on a regular basis, ensuring that your equipment and machinery is continually checked for both minor and major problems. Even small electrical problems can become more severe issues if left undetected for too long, which can lead to emergency repairs that require halted production lines and costly replacement parts. In a challenging global economy that demands cost-effective mass production on a timely basis, stopping production due to equipment failure can have major setbacks.

A Safer Workplace:

Not only can preventive electrical maintenance save businesses time and money, but by keeping equipment functioning properly, the risk of hazard is greatly reduced and the work environment becomes a safer place. Electrical equipment failure can lead to serious hazards, including fires and arc flash, which can leave workers severely injured. Equipment that is not working properly or problems that are left undetected can have unfortunate results for electricians working with or near the equipment. Machinery should be inspected frequently to identify potential problems and prevent them from becoming dangers in the workplace.

Using Infrared Thermograph:

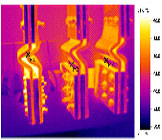

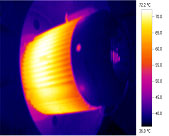

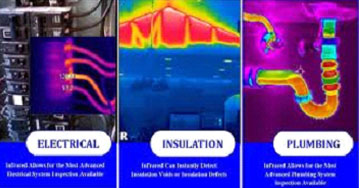

The use of infrared (IR) thermography is critical to preventive maintenance in electrical work environments. All objects radiate thermal energy, or heat, and IR cameras can detect the radiation of heat that is emitted from any given object by taking "heat" images. Through a range of colors, these images present hot spots that cannot otherwise be perceived by the naked eye. IR thermograph is used to reveal loose circuits, equipment failure and safety hazards. Electrical workers can then use the thermographic images to analyze and measure temperatures, identifying problems and fixing them before they become severe.

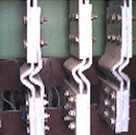

THERMOGRAPH STUDY - SAMPLE IMAGES

Electrical Distribution & Equipments

|

|

|

|

Building –Thermal Envelope

|

|

|

|

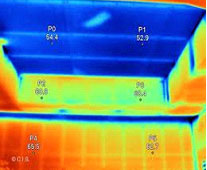

HVAC –Insulation Monitoring

|

|

|

|